Heat Transfer Label

Heat transfer film is the origin for all of Nissha’s decoration technologies, making Nissha the world-class leader in the field of surface treatments.

Ever since Nissha developed Japan’s first transfer foil, this unique technology has long been admired high quality decoration method for cosmetics, stationaries, daily goods, consumer electronics and appliances.

Key benefits

Multi-color decoration

Multi-color decoration (max 10 color) is available just by single heat transfer process. This enable to reduce many after process and allow to save production cost.

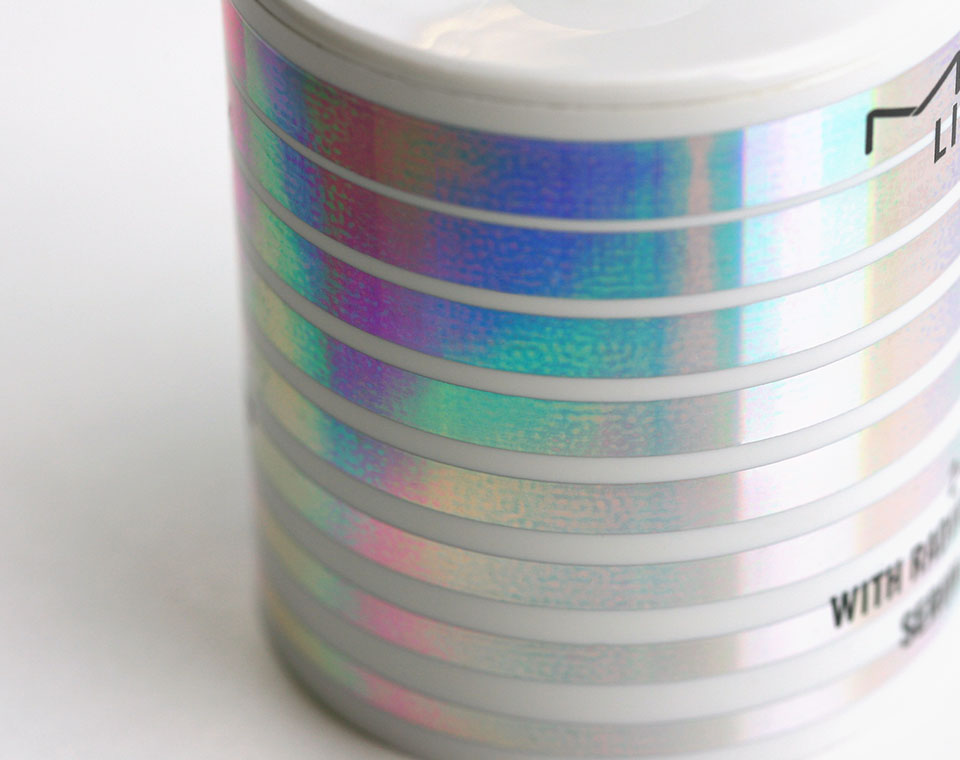

Shiny mirror effect

Vacuum metallization technology reproduces shiny mirror effect which enhance visual appealing for logo or special graphic.

Decoration on any substrate

Heat Transfer film enables decoration not only for plastic molded products but also for its composites, glass, metal, and even leather.

Small volume to high scale

Screen printed film for small volume and high speed gravure printing for big volume production. Variety of printing solution could deal with any q’ty of project.

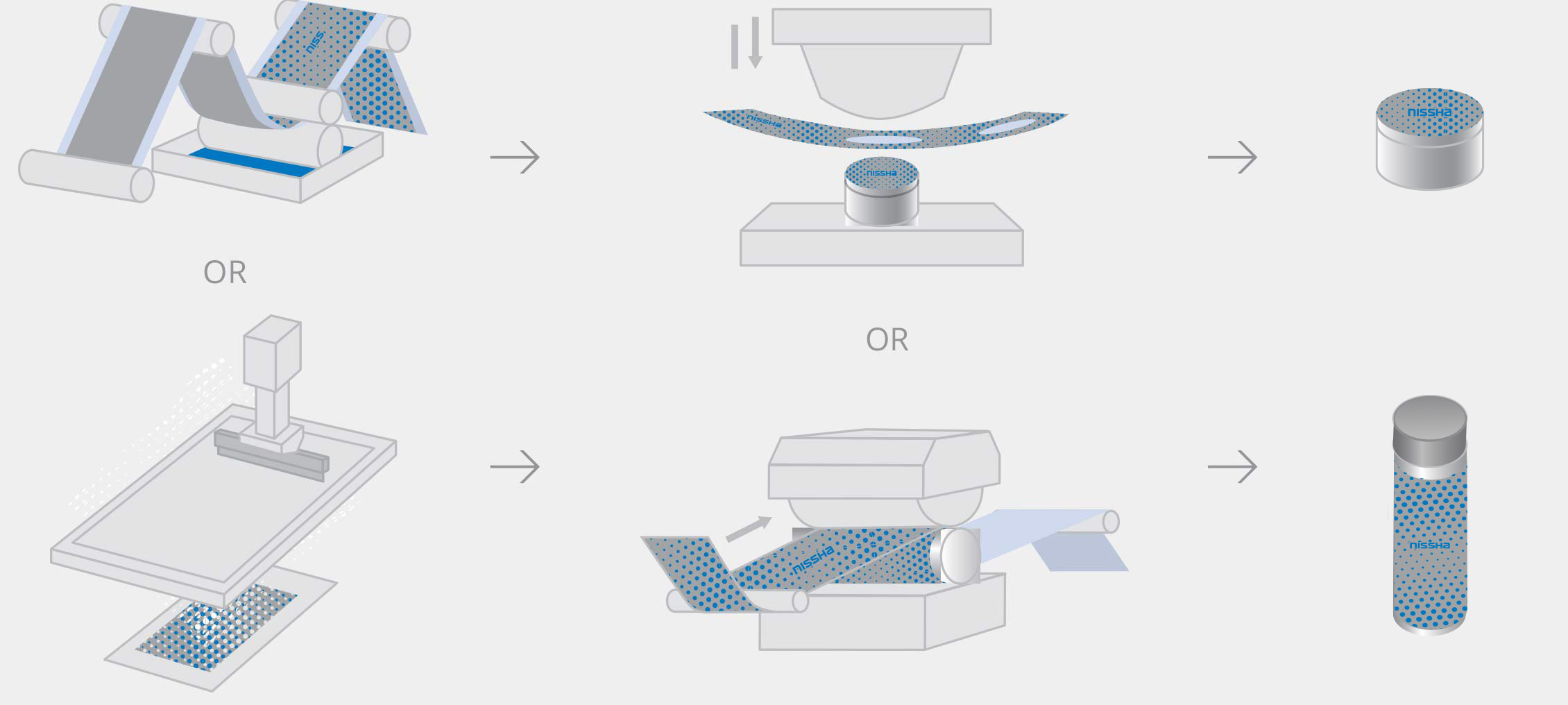

Process

Heat transfer is a post molding decoration process – which applies versatile colors and finishes onto parts made (molded) in advance.

The process is fast with high productivity, making decoration by heat transfer film a competitive solution for the cosmetic packaging and stationery industries.

Composition

Process Flow

Printing

Heat transfer film is manufactured by gravure printing, silk screen printing, and even digital printing depending on technical specification and production lot size.

Heat transferring

Depending on the shape of the parts, the roll heat transfer method or the up-down heat transfer method may be used.

Heated silicon rubber or roll presses the foil against transfer parts.

Product

Decoration can be done on either flat geometry (by up-down method) and cylindrical shape (by roll type method).

Multiple printing method of Nissha HTF

Design

Price

MOQ

L/T

Technical Specification

Printing method for Heat Transfer Film

Gravure printing, Sink screen printing, Digital printing, Vacuum metallization

Substrate

ABS, PP, PET, PETG, PC, PC/ABS, HDPE, Glass, Aluminum, Leather, etc…

Maximum colors in one film

8 -10 colors by screen/gravure, CMYK+white by Digital

Surface finish

High gloss, Matte, Partial matte, Shiny mirror finish (VM)

Heat transfer process

Roll type, Up-down type, Vacuum press type

Q & A

What kind of shapes can you apply Heat Transfer film onto?

Typical geometries are flat surfaces, one direction curved surfaces, and cylindrical shapes. For specific complex 3D geometry, Nissha will test and study its feasibility. If it’s too complex, we can offer other technology like IMD or IML.

Does Nissha provide equipment needed for Heat Transfer Film production? Also, is it possible to get technical support?

Yes, Nissha sells Heat Transfer Machines and the heat transfer fixture for each product geometry. Also, we can support customers and customer’s supply chain to install the Heat Transfer Machines and ramp up successfully.

What kind of substrate can be used with Nissha Heat Transfer Film?

A variety of substrates can be decorated with our Heat Transfer Film. Mainly our heat transfer film is used in plastic parts decoration, like PP, PS, PC, and ABS. Nissha also offers heat transfer for other materials such glass, metal, and even fabric by using an optimized adhesion layer.